Aluminum Powder Coating Is the Best Choice for Your Product Finish

Updated: 20 Jun 2023

What is Aluminum Powder Coating Process

The aluminum powder coating process is a method used to apply a protective and decorative coating to aluminum surfaces. Powder coating involves applying a dry powder to the surface, which is then heated to create a smooth and durable finish. Here are the main steps involved in the aluminum powder coating process:

Pre-treatment: After the surface is clean, a pre-treatment process is usually applied to improve adhesion and corrosion resistance. Common pre-treatment methods for aluminum include etching or chemical conversion coating. Etching involves using an acid or alkaline solution to create a microscopically rough surface, while chemical conversion coating involves the application of a conversion coating material that reacts with aluminum to form a protective layer.

Powder Application: The powder coating is applied once the pre-treatment is complete and the surface is dry. The powder typically comprises finely ground particles of colored resin, pigments, and additives. Various methods exist for applying the powder, including electrostatic spray, fluidized bed dipping, or an airless spray system.

Electrostatic Spray: This is the most common method for powder coating aluminum. The powder is electrically charged and sprayed onto the surface using a spray gun. The charged particles are attracted to the grounded aluminum surface, creating a uniform coating.

Fluidized Bed Dipping: In this method, the aluminum part is preheated, and then it is dipped into a fluidized bed of the powder coating material. The heat causes the powder to melt and adhere to the surface, forming a coating.

Airless Spray: This method uses a specialized spray gun that atomizes the powder and applies it to the surface without using an electrostatic charge. The powder particles are propelled onto the surface using high-pressure air or gas.

Curing: After applying the powder, the coated aluminum part is heated to cure the coating. Curing is typically done in a curing oven, where the coated part is exposed to high temperatures for a specific duration. The powder particles melt, flow, and chemically crosslink during this process, forming a continuous and durable coating. The curing temperature and time depend on the specific powder coating material used.

Cooling and Inspection: The coated aluminum part can cool down to room temperature once the curing process is complete. After cooling, a visual inspection is performed to ensure the coating is uniform, free from defects, and meets the desired specifications. Any necessary touch-ups or repairs may be done at this stage.

The aluminum powder coating process offers several advantages, including excellent durability, resistance to corrosion, and a wide range of color options. It is commonly used in various industries, including automotive, architecture, furniture, and appliances.

Advantages of aluminum powder coating:

Lightweight and High Strength: Aluminum is a lightweight metal with good strength and stiffness. Aluminum spraying creates a solid layer of aluminum over the surface of an object, providing extra protection and added strength without adding too much weight.Corrosion resistance: Aluminum has good corrosion resistance, preventing objects from being eroded by anodized corrosion and chemicals. Aluminum spraying can form a protective layer and prolong the object's life.

Thermal conductivity: Aluminum has good thermal conductivity and can conduct heat quickly. Aluminum spraying can be applied to the surface of objects that need heat dissipation, such as electronic equipment, radiators, etc., to improve heat dissipation efficiency.

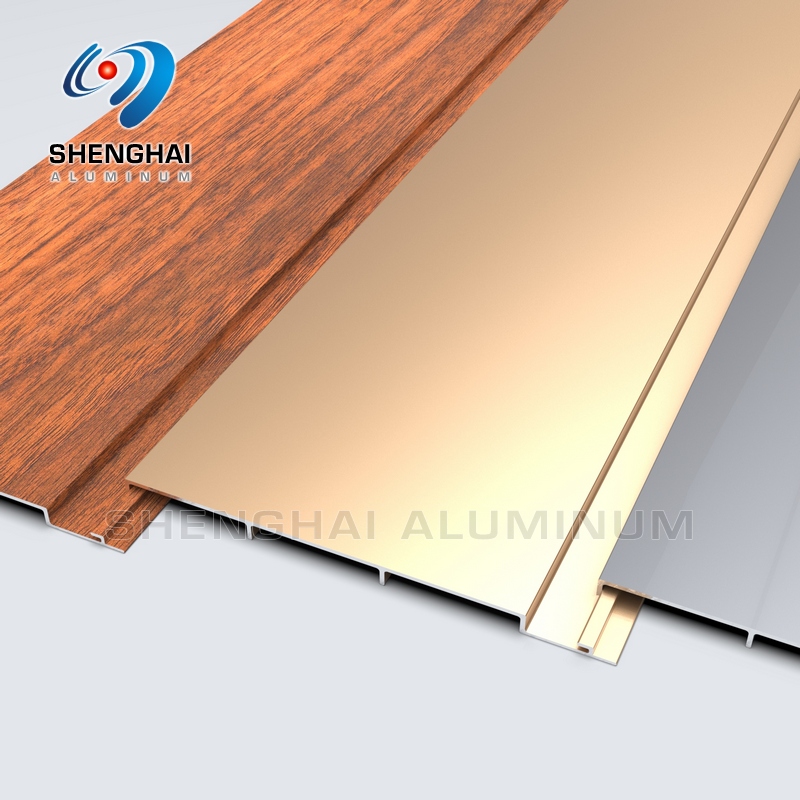

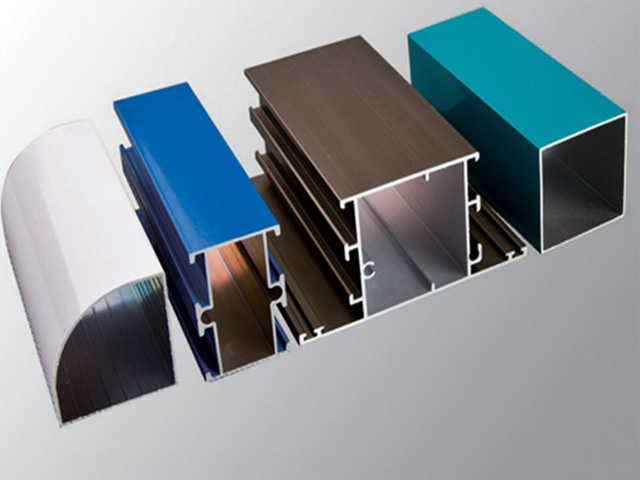

Decorative effect: Aluminum powder coating can give the object's surface a metallic texture and a sense of modernity, enhancing its appearance and decorative effect. At the same time, aluminum powder coating can provide different color and texture options to meet individual design needs.

Shenghai Aluminum powder coating products

Broken bridge aluminum doors and windows, aluminum ceilings, aluminum edge strips, aluminum electronic heat sink, etc.

Shenghai Aluminum is a company that focuses on comprehensive aluminum profiles and customized services for aluminum products. Our independent design and R&D team is dedicated to optimizing user programs, developing aluminum profile molds, and performing aluminum profile extrusion and CNC machining. We also provide comprehensive surface treatment services to ensure the quality and appearance of aluminum profiles. No matter your aluminum profile needs, we can provide professional solutions and implement them according to your specific requirements. If you are interested in our services or have any needs related to aluminum profiles, please contact us immediately.

We look forward to cooperating with you.