Aluminum Profiles Become the Best Choice for Solar Industry

Updated: 23 May 2023

Why Aluminum Extrusions Are Used in Solar Panel Designs

In the design of solar panels, aluminum profiles can be used to make frames and support structures. Aluminium extrusions are often used to hold the surface glass of a solar panel and protect the solar cells and other components. The support structure is used to support the weight of the entire solar panel and mount it in the desired location, such as a roof or ground mount.Lightweight: Aluminum alloy is lightweight yet strong, making aluminum extrusions ideal for solar panel designs. Solar panels often need to be mounted on a roof or other support structure, so lightweight materials can lighten the load and simplify installation.

Corrosion Resistance: Solar panels typically operate outdoors and are exposed to a variety of climatic conditions, including heat, humidity, and rainfall. Aluminium profile has good corrosion resistance and can effectively resist oxidation and corrosion, thereby prolonging the service life of solar panels.

Thermal conductivity: Solar panels will generate heat during operation, if not dissipated in time, it may affect the performance and efficiency of the panels. Aluminum profile has good thermal conductivity, which can help quickly conduct and dissipate heat to the surrounding environment, keeping the temperature of the battery panel within an appropriate range.

Ease of processing: Aluminum profiles are relatively easy to perform processing operations such as cutting, bending, and connection and can be customized according to the design requirements of solar panels. This malleability makes aluminum extrusions ideal for manufacturing solar panels of complex shapes and structures.

Which aluminum profiles are used for photovoltaics

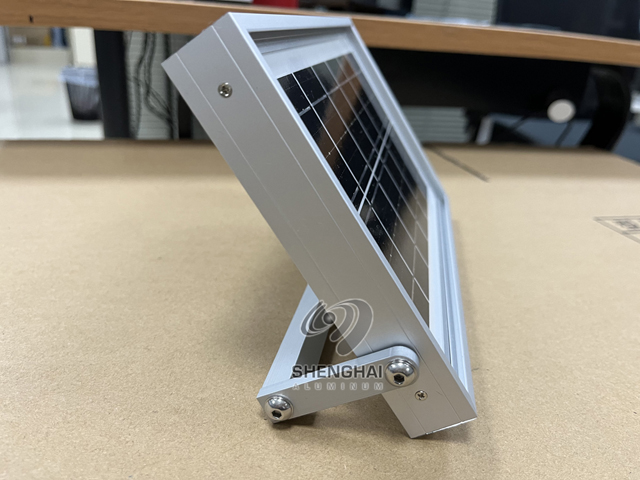

1. Solar frame, also called a photovoltaic aluminum frame, is mainly used to protect the glass of photovoltaic cells, fix and seal the panels, enhance the strength of components, and prolong the service life. The cross-section of the photovoltaic frame is L-shaped with a notch, and there is a cavity for installing corner code connectors. Most solar frames are made of 6005 aluminum alloy, and the surface is anodized silver, white or black.2. Photovoltaic support is a special support designed to place, fix and support solar panels during the construction of photovoltaic power plants. The solar photovoltaic bracket is made of aluminum alloy, carbon steel, stainless steel, etc. The surface requirements of the photovoltaic support are not as high as the photovoltaic frame. The aluminum alloy support is generally anodized, and the surface of the steel support is galvanized to prevent outdoor oxidation and corrosion.

According to the different movable performances, photovoltaic support can be divided into fixed, adjustable, and tracking photovoltaic support. The stability, load and safety performance requirements of photovoltaic support are relatively high.

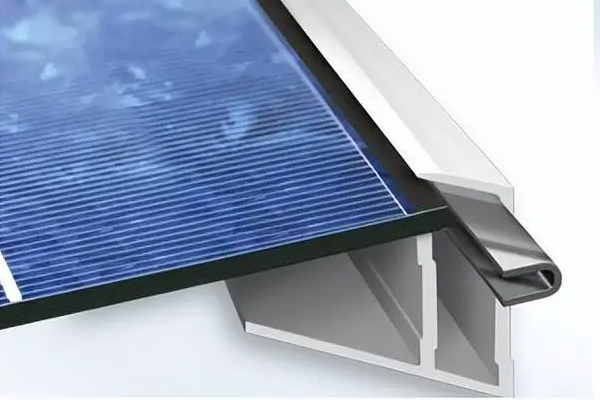

3. Photovoltaic compacts, also called solar panel compacts, play the auxiliary role of brackets and are used to install and fix solar panels. Photovoltaic compacts are divided into side compacts and middle compacts.

The middle compact connects two adjacent battery panels, while the side compact is used as the connection between the photovoltaic panel and the support. In some double-glass frameless modules, the compact directly clamps the photovoltaic glass and then connects to the bracket. The material of the compact is generally 6063 aluminum alloy, and the surface is anodized.

Aluminum extrusions play an important role in the energy and power industry, and these properties make them indispensable components. Although other metals are used to manufacture solar panels, these materials are expensive. Aluminum extrusions cost less, and we may need twice as much aluminum as other metals when building new solar panels. This advantage reduces operating costs in the energy sector.

There is no doubt that aluminum extrusions will play an important role in shaping new applications in green and renewable energy. For example, 6063 aluminum alloy, which is widely used in the solar field, has proved to be an indispensable material in the past few decades. Aluminum is unrivalled for its economy, flexibility and performance over other materials. When finding the perfect material, we are dedicated to meeting your needs. Please feel free to contact us for more information on the capabilities of aluminum extrusions and to choose a suitable alloy. Whether you work in the solar industry or green energy, we're here to meet your specific needs and help you thrive.

.jpg)