Benefits of Choosing Anodized Aluminum Profile

Updated: 10 Jan 2023

What is anodized aluminum profile

Anodizing is a process that creates a dense natural film on the surface of aluminum profiles. This film makes the surface harder and more resistant to wear, against corrosion and anti-oxidation. Aluminum anodized finish usually uses electrolysis to create the film, where an anode (usually aluminum or aluminum alloy) is placed on the surface of the aluminum profile and a cathode is placed in solution. The redox reaction occurs through an electric current, resulting in a dense natural film on the surface of the anode. The thickness of this film can be controlled by adjusting the current strength, solution concentration and time.

Which is better stainless steel or anodized aluminum profile

Stainless steel and anodized aluminum profile are better materials but behave differently in specific situations.Stainless steel is a corrosion-resistant alloy with good machinability and strength. Its greatest advantage is that it is highly resistant to corrosion and can be used in many situations. However, the disadvantage of stainless steel is that it is more expensive, has poor thermal conductivity and is not very suitable for high temperature situations.

Anodized aluminum extrusions are thin film materials obtained by anodizing the surface of aluminium profiles. It has good corrosion resistance, abrasion resistance, electrical insulation and electrical conductivity. At the same time, anodized aluminum is relatively inexpensive compared to stainless steel, but it is less hard and may not be very suitable for some specific use cases.

Therefore, if you are in construction or industry, you can choose anodized aluminum. Not only is it easy to process, but it also has a favourable price.

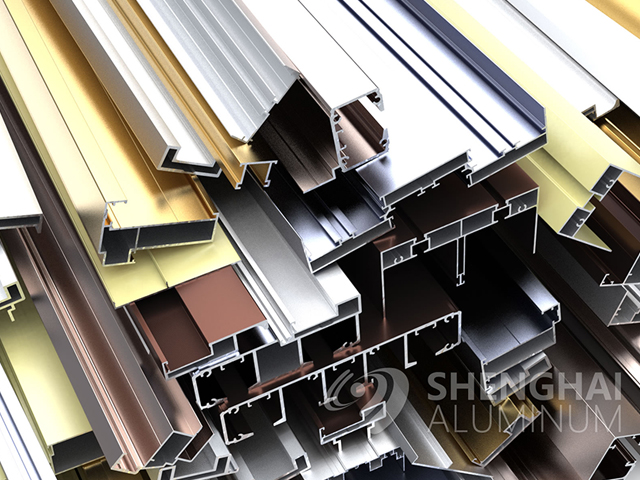

Which aluminum profile products are suitable for anodizing

Anodizing aluminum profiles is a common coating process that forms a dense, hard oxide film on the surface of aluminium profiles. This oxide film can improve the corrosion and wear resistance of aluminum profiles and their appearance.1. Aluminum alloy profile: It has better processing performance and higher strength, so it is often used in manufacturing mechanical parts, building components and transportation, etc.

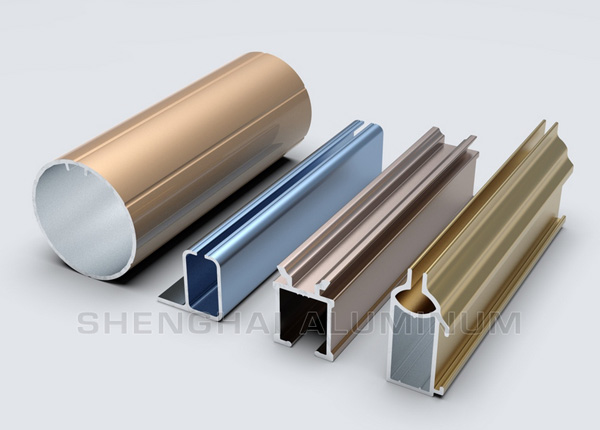

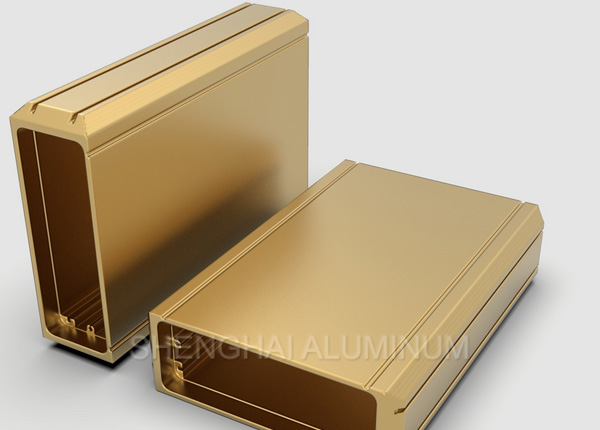

2. Aluminum profile board: aluminum profile board refers to the flat profile made of aluminum, commonly used in manufacturing boxes, electronic products shells, etc.

3. Aluminum profile tube: aluminum profile tube refers to the cylindrical or rectangular profile made of aluminum, commonly used in the manufacture of pipes, bearing housings, etc.

It should be noted that different aluminum profile products may need to use other process parameters when anodizing, so they should be adjusted according to the characteristics of specific products when anodizing.

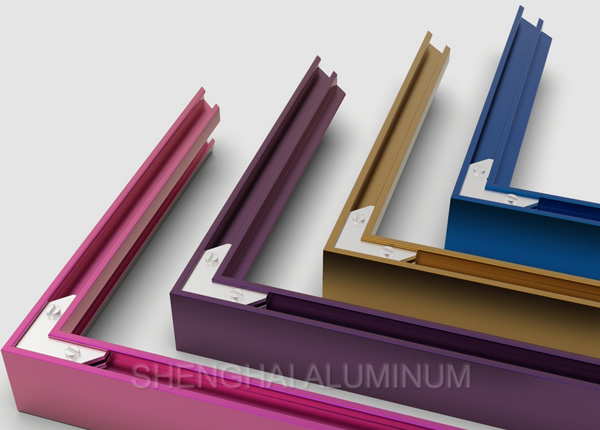

Anodizing is a commonly used surface treatment method that can treat the surface of aluminum profiles into a thick oxide film. This anodized film has good corrosion and abrasion resistance, which can effectively protect the surface of aluminum profiles from damage. Anodizing can also improve the aesthetics of aluminum profiles, giving the surface a good luster and color. In addition, anodizing has good electrical insulation properties and can be used to manufacture electrical components. Therefore, choosing anodized aluminium profiles can bring many benefits.