Get More Knowledge Of Aluminum Extrusion Bending

Updated: 10 Jan 2024

In life, many aluminum profile projects require the bending process. Bending technology can make aluminum materials more adaptable and have a wider range of applications. However, not all aluminum profile manufacturers can implement the bending process. After all, this process still requires specific technical support.

Therefore, when choosing a bending process, you must consider the project's design requirements and choose a more cost-effective processing method. Not only can the project show better results, but it can also save costs and improve the product's competitiveness in the market.

Aluminum profile bending application

Aluminum profile bending application

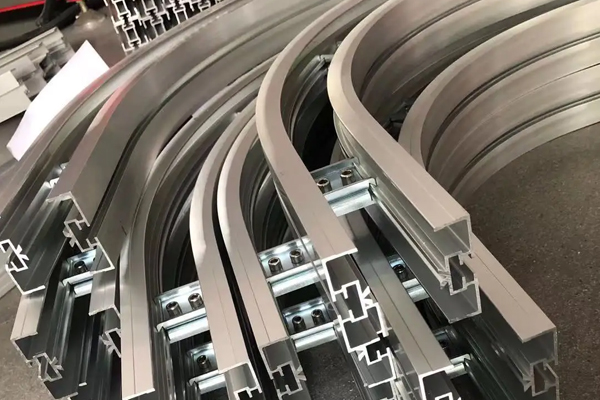

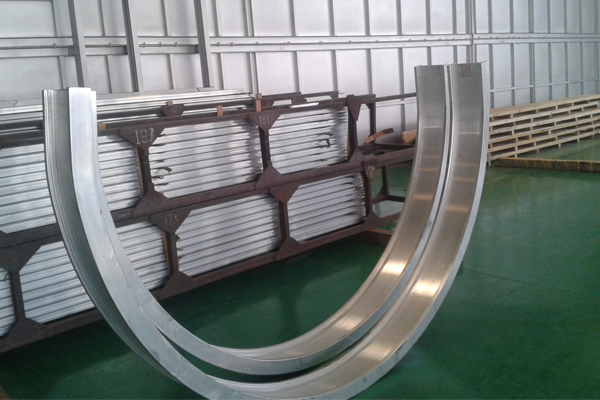

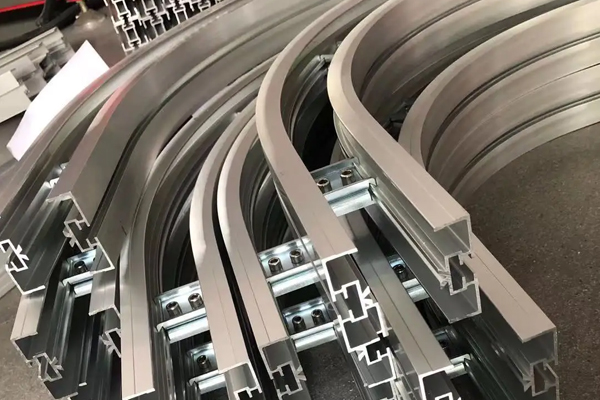

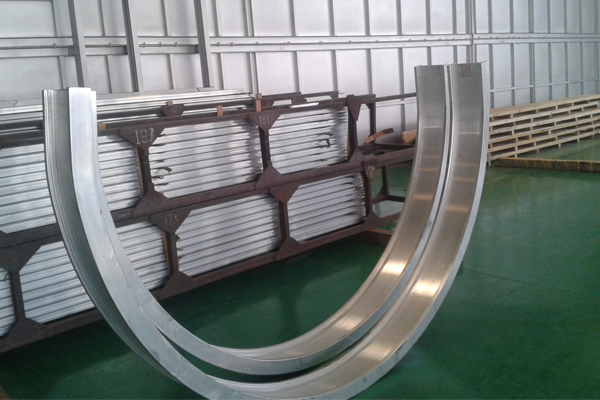

Bending aluminum profiles are widely used in construction and industry. Typical applications include door and window frames, ceilings, curtain walls, T slots (industrial profiles), electronic enclosures, light frames, solar brackets, etc. The material we often use is aluminum alloy 6000 series, and we provide aluminum processing services such as oxidation, powder coating, welding, and bending.

Choose Shenghai Aluminum to obtain high-quality aluminum profile products quickly. Please contact us now.

Good Bending Technology Can Save Time On Aluminum Projects

As a professional aluminum profile manufacturer, we all know that technical support is crucial to complete the delivery of an aluminum profile project quickly. Shenghai Aluminum has more than 15 years of experience in bending technology. Our engineers are very mature in bending technology. Completed projects with different bending angles, bending radii, etc. The bent aluminum profiles that Shenghai Aluminum often comes into contact with include 90-degree bending, bent U channel, bent V-shaped channel, bent circular and ring shapes, etc. For bending projects with longer aluminum profiles, it is very large. Because surface cracks will appear during the bending process, this may be caused by excessive bending force or the grade of the aluminum alloy. Profile extrusion and processing procedures will affect the bending effect to obtain aluminum profile bending products quickly. Therefore, choosing a one-stop service manufacturer for aluminum profile extrusion and aluminum fabrication is very important. You can trust us if your project is very tight on time and you want to get good results.How To Make Your Aluminum Extrusion Bending Project More Cost-effective

We all know that there are many kinds of aluminum extrusion bending processes, but according to the different uses of the profile, the bending methods used are also other. For example, some project designs require a small bending angle and small bending radius for bent aluminum materials to use cold bending. Many construction and home decoration project designs (such as aluminum light frame shells, ceilings, picture frames, skirting lines, etc.) mostly use cold bending methods. Profiles that use thermal bending are profile projects requiring complex shapes and large bending angles.Therefore, when choosing a bending process, you must consider the project's design requirements and choose a more cost-effective processing method. Not only can the project show better results, but it can also save costs and improve the product's competitiveness in the market.

Bending aluminum profiles are widely used in construction and industry. Typical applications include door and window frames, ceilings, curtain walls, T slots (industrial profiles), electronic enclosures, light frames, solar brackets, etc. The material we often use is aluminum alloy 6000 series, and we provide aluminum processing services such as oxidation, powder coating, welding, and bending.

Choose Shenghai Aluminum to obtain high-quality aluminum profile products quickly. Please contact us now.