How To Choose Aluminum Alloy 6061 or 6063

Updated: 26 Feb 2024

Aluminum alloy 6061 has good formability, weldability, and machinability. Moreover, 6061 has good processing performance, good corrosion resistance, high toughness, no deformation after processing, easy coloring film, and excellent oxidation effect.

The elemental composition of aluminum 6061 is:

Aluminum (Al) – 95.9-98.6%

Chromium (Cr) – 0.04-0.35%

Copper (Cu) – 0.15-0.4%

Iron (Fe) – Up to 0.7%

Magnesium (Mg) – 0.8-1.2%

Manganese (Mn) – Up to 0.15%

Silicon (Si) – 0.4-0.8%

Titanium (Ti) – Up to 0.15%

Zin (Zn) – Up to 0.25%

Residual elements – Up to 0.15%

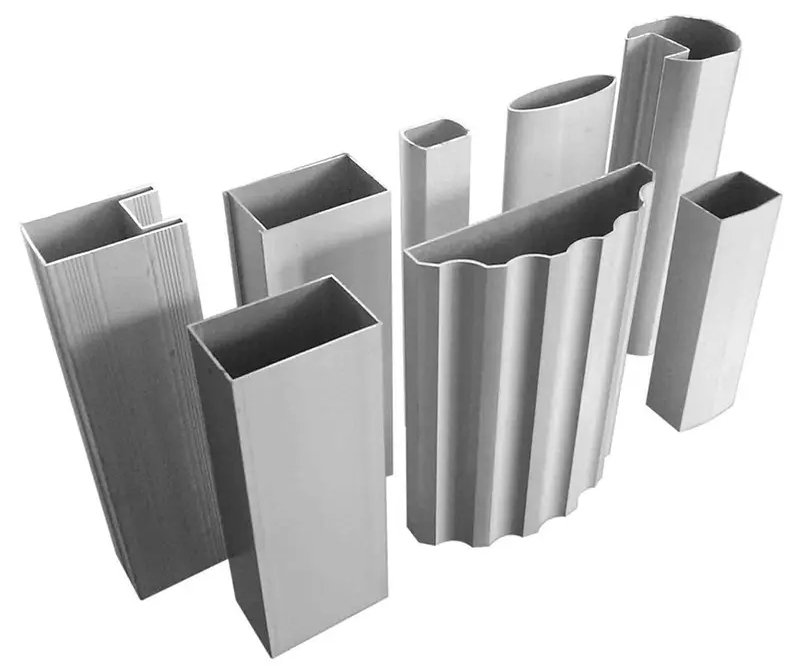

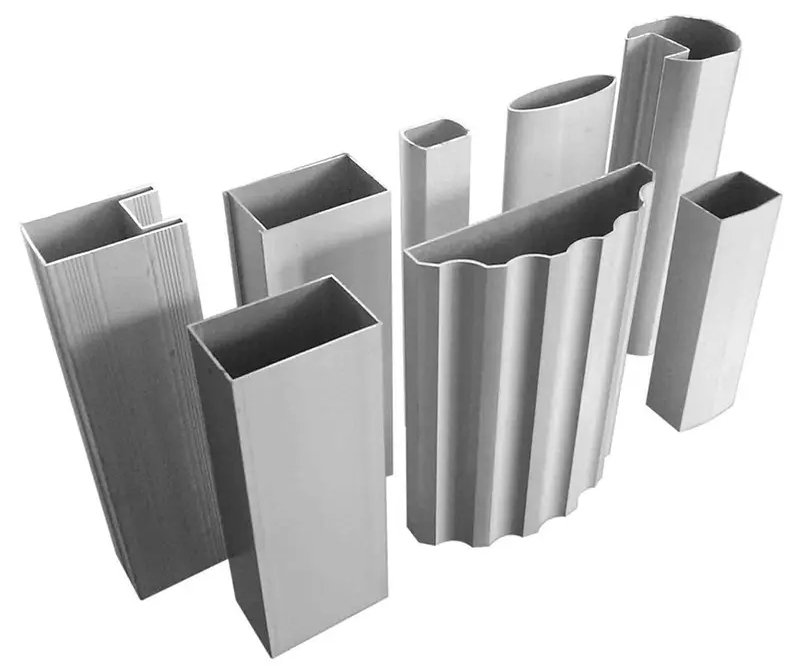

6063 is a deformed aluminum alloy that can be strengthened by heat treatment and has a lower strength than 6061. It has excellent extrusion formability, processing performance, and corrosion resistance. After oxidation coloring and spray surface treatment, the surface is smooth, and the color is beautiful; it is widely used in door and window building materials, home decoration, appearance components of consumer electronics, and interior parts of automobiles.

The elemental composition of aluminum 6061 is:

Aluminum (Al) – 95.9-98.6%

Chromium (Cr) – 0.04-0.35%

Copper (Cu) – 0.15-0.4%

Iron (Fe) – Up to 0.7%

Magnesium (Mg) – 0.8-1.2%

Manganese (Mn) – Up to 0.15%

Silicon (Si) – 0.4-0.8%

Titanium (Ti) – Up to 0.15%

Zin (Zn) – Up to 0.25%

Residual elements – Up to 0.15%

Do you need help deciding which alloy to choose for your aluminum profile project? This article by Shenghai Aluminum can guide you in choosing between 6061 and 6063.

The difference between 6061 and 6063

There are some differences between 6061 and 6063 aluminum alloys in terms of chemical composition, mechanical properties, heat treatment capabilities, application, surface treatment, etc.:

Chemical composition: 6061 aluminum alloy has higher magnesium and silicon content, while 6063 aluminum alloy has higher silicon and manganese content, making 6061 slightly stronger and corrosion-resistant.

Machinability: 6061 has higher tensile strength and yield strength, while 6063 aluminum alloy has higher elongation and impact resistance.

Heat treatment capabilities: 6061 has good heat treatment ability. It can obtain higher strength through heat treatment, while 6063 has poor heat treatment ability and the effect of heat treatment is less significant than 6061 aluminum alloy.

Strength: 6061 has higher tensile strength and yield strength than 6063.

Corrosion resistance: In the aluminum billet state, 6061 is better than 6063.

Application: 6061 aluminum alloy is commonly used in structural components, aircraft components, and marine applications, while 6063 aluminum alloy is commonly used in architectural applications such as window frames, door frames, and curtain walls.

Surface treatment: 6061 usually uses surface treatment methods such as anodization to improve corrosion resistance and appearance quality. Meanwhile, 6063 usually uses surface treatment methods such as colored electrophoresis and powder coating to improve appearance and enhance anti-oxidation properties.

In general, 6061 aluminum alloy is superior to 6063 aluminum alloy in terms of strength, corrosion resistance, heat treatment ability, etc. In contrast, 6063 aluminum alloy performs better in processing performance, price, etc.

If your aluminum profile project requires higher strength and hardness, you can choose 6061.

If you want good processing performance, 6063 is the best. 6063 is widely used in construction, decoration, etc.

Shenghai Aluminum is a professional aluminum profile manufacturer. We can provide various grades of aluminum alloy materials to meet any customer needs. Common aluminum alloys include 6061, 6063, 7075, 7005, 5086, 5082, 2024, etc. Our aluminum profiles are not only of good quality, but also very competitively priced. You can contact us immediately if you are looking for an aluminum extrusion factory.

The elemental composition of aluminum 6061 is:

Aluminum (Al) – 95.9-98.6%

Chromium (Cr) – 0.04-0.35%

Copper (Cu) – 0.15-0.4%

Iron (Fe) – Up to 0.7%

Magnesium (Mg) – 0.8-1.2%

Manganese (Mn) – Up to 0.15%

Silicon (Si) – 0.4-0.8%

Titanium (Ti) – Up to 0.15%

Zin (Zn) – Up to 0.25%

Residual elements – Up to 0.15%

The elemental composition of aluminum 6061 is:

Aluminum (Al) – 95.9-98.6%

Chromium (Cr) – 0.04-0.35%

Copper (Cu) – 0.15-0.4%

Iron (Fe) – Up to 0.7%

Magnesium (Mg) – 0.8-1.2%

Manganese (Mn) – Up to 0.15%

Silicon (Si) – 0.4-0.8%

Titanium (Ti) – Up to 0.15%

Zin (Zn) – Up to 0.25%

Residual elements – Up to 0.15%

Do you need help deciding which alloy to choose for your aluminum profile project? This article by Shenghai Aluminum can guide you in choosing between 6061 and 6063.

The difference between 6061 and 6063

There are some differences between 6061 and 6063 aluminum alloys in terms of chemical composition, mechanical properties, heat treatment capabilities, application, surface treatment, etc.:

Chemical composition: 6061 aluminum alloy has higher magnesium and silicon content, while 6063 aluminum alloy has higher silicon and manganese content, making 6061 slightly stronger and corrosion-resistant.

Machinability: 6061 has higher tensile strength and yield strength, while 6063 aluminum alloy has higher elongation and impact resistance.

Heat treatment capabilities: 6061 has good heat treatment ability. It can obtain higher strength through heat treatment, while 6063 has poor heat treatment ability and the effect of heat treatment is less significant than 6061 aluminum alloy.

Strength: 6061 has higher tensile strength and yield strength than 6063.

Corrosion resistance: In the aluminum billet state, 6061 is better than 6063.

Application: 6061 aluminum alloy is commonly used in structural components, aircraft components, and marine applications, while 6063 aluminum alloy is commonly used in architectural applications such as window frames, door frames, and curtain walls.

Surface treatment: 6061 usually uses surface treatment methods such as anodization to improve corrosion resistance and appearance quality. Meanwhile, 6063 usually uses surface treatment methods such as colored electrophoresis and powder coating to improve appearance and enhance anti-oxidation properties.

In general, 6061 aluminum alloy is superior to 6063 aluminum alloy in terms of strength, corrosion resistance, heat treatment ability, etc. In contrast, 6063 aluminum alloy performs better in processing performance, price, etc.

If your aluminum profile project requires higher strength and hardness, you can choose 6061.

If you want good processing performance, 6063 is the best. 6063 is widely used in construction, decoration, etc.

Shenghai Aluminum is a professional aluminum profile manufacturer. We can provide various grades of aluminum alloy materials to meet any customer needs. Common aluminum alloys include 6061, 6063, 7075, 7005, 5086, 5082, 2024, etc. Our aluminum profiles are not only of good quality, but also very competitively priced. You can contact us immediately if you are looking for an aluminum extrusion factory.