How To Choose Thermally Broken Aluminum Window And Door

Updated: 2 Jan 2025

In home decoration, windows are an important factor affecting the quality of the living environment. Among the many types of doors and windows, thermal break aluminum doors and windows are favored by consumers for their excellent thermal insulation and excellent sealing performance. However, due to the relatively high price of thermally broken aluminum doors and windows, there is a phenomenon of uneven quality in the market. So, how can you choose high-quality thermal break aluminum doors and windows? Shenghai Aluminum provides you with a professional purchase guide.

Profile thickness

In fact, the performance of aluminum profiles is not the thicker the wall thickness, the better. The material and cavity structure also play a key role.

Aluminum profiles are mainly divided into primary aluminum and recycled aluminum. Primary aluminum is refined and processed from aluminum ore and has high quality; recycled aluminum is made by remelting recycled waste aluminum products. Its performance is relatively inferior, but as a civilian aluminum material encouraged by the state, it has environmental value. A simple way to distinguish primary aluminum from recycled aluminum is to observe the cut surface: the cut surface of primary aluminum is flat, burr-free, and has a bright blue-black color; the cut surface of recycled aluminum is prone to burrs, and the color is silvery white.

In addition, the quality of aluminum profiles is also related to the aluminum alloy model. At present, 6063 aluminum alloys, such as 6063-T5 and 6063-T66, are widely used in door and window profiles. These types of aluminum alloys have excellent hardness and toughness and are the preferred materials for high-end profiles.

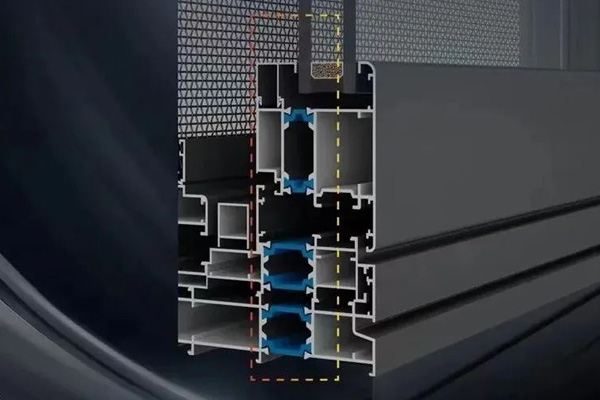

The performance of the profile is also closely related to the cavity structure. For example, profiles with multi-cavity structures perform better than single-cavity structures in terms of heat insulation and sound insulation. Under the same material and structural conditions, profiles with thicker walls perform better, but the cost will also increase. Therefore, to judge the quality of aluminum profiles, it is necessary not only to look at the wall thickness, but also to comprehensively consider the material and cavity structure to ensure that high-quality products are purchased.

Number of glass layers

Today's system windows are basically standard for hollow glass, mainly with double-layer hollow and triple-layer hollow options. High-end configurations usually use tempered glass with 5mm per layer. Triple-layer hollow glass is widely used in cold areas in winter, and its heat insulation and sound insulation performance are better than double-layer hollow glass.

Is there a choice with more layers? There are indeed four-layer hollow and even laminated glass, but in actual applications, double and triple layers are still the mainstream. Although the increase in the number of glass layers has improved some performance, it also brings the following problems:

Increased weight: Multi-layer glass increases the overall weight of the window, exerting greater pressure on the frame, which may cause deformation. Especially in the outward-opening windows commonly used in the south, excessive glass will accelerate the loss of hardware and even cause safety hazards.

Decrease in light transmittance: As the number of glass layers increases, the overall light transmittance will decrease, affecting the indoor lighting effect.

Visual distortion: After tempering, the glass will produce a certain degree of deformation. The more layers, the more obvious the distortion effect.

Rising costs: The increase in the number of glass layers also directly pushes up the production and installation costs.

Therefore, usually double or triple layers of hollow glass are sufficient to meet the thermal and sound insulation needs of most families. Unless there are special needs, such as extreme sound insulation, heat insulation or explosion-proof requirements, there is no need to choose too many layers of glass to avoid an imbalance between performance improvement and other problems.

Glass

Many door and window salespeople will recommend Low-E glass, which is indeed an excellent energy-saving technology. It can significantly improve the heat insulation performance of glass, effectively block ultraviolet rays, and have a certain privacy protection effect. However, Low-E glass is not suitable for all occasions.

First, it may not be suitable for families who like to grow flowers. Because Low-E glass reduces the transmission of ultraviolet rays, some plants may not get enough light to complete normal photosynthesis. Secondly, the light transmittance of Low-E glass is about 10% lower than that of ordinary glass. If it is a small apartment, especially in a space with poor lighting conditions, the use of this glass may further reduce the brightness of the room.

Therefore, when purchasing Low-E glass, you should combine the family's actual needs and the environment in which it will be used to ensure that you can enjoy the energy-saving effect without affecting your living comfort.

Number of sealing layers

Number of sealing layers

The number of sealing layers refers to the number of sealing structure layers between the door and window frames and sashes. Standard system doors and windows usually adopt a three- to five-layer sealing design. However, in order to attract consumers, some manufacturers will make the sealing strips into multiple convex ridges and promote them as eight-layer, ten-layer or even more-layer sealing structures. In fact, this statement is more of a marketing gimmick. Too many sealing layers may cause the strips to connect. Once one layer fails, other layers may fail together, thereby reducing the overall sealing performance.

The key to judging the sealing performance of doors and windows lies not only in the number of sealing layers but also in the material of the sealing strip. High-quality sealing strips usually use EPDM, which is an automotive-grade sealing material. Currently, high-end products also have EPDM soft and hard co-extruded strips, which have good elasticity, are not easy to age, have a bright and clean surface, and have no odor. And those sealing strips that look greasy and emit pungent odors are often of poor quality. Even if there are more sealing layers, it is difficult to guarantee the sealing performance of doors and windows with inferior strips.

Therefore, when purchasing doors and windows, you should pay attention to the material and design of the sealing strip rather than blindly pursuing the concept of "multi-layer sealing" to ensure the long-term performance and use experience of doors and windows.

Profile insulation strip

The broken bridge aluminum is named because a kind of insulation strip is embedded in the middle of the profile, forming a "thermal break" structure, which effectively prevents the transfer of heat.

So, is the wider the insulation strip, the better? Not really. If the insulation strip is too wide, the aluminum part will become smaller, which may reduce the overall strength of the profile and affect its stability and service life.

In addition, the material of the insulation strip is also crucial. Common insulation strip materials are divided into nylon PA66 and PVC. Nylon PA66 insulation strips are superior to PVC materials in terms of strength, heat resistance, and aging resistance. Therefore, when purchasing broken bridge aluminum doors and windows, you should pay attention not only to the width of the insulation strip but also to its material to ensure the reliability and superiority of the overall performance.

Hardware

Hardware is the "soul" of doors and windows, directly affecting their opening method, sealing, and service life. At present, common door and window hardware include traditional types such as inner opening, outer opening, and inner opening and tilting. In recent years, some high-end hardware has also appeared, such as hidden inner opening and tilting hardware and intelligent opening hardware.

When choosing door and window hardware, it is recommended to give priority to some traditional and common hardware types. These hardware technologies are mature, durable, not easy to damage, and more convenient to maintain and replace later, and the price is relatively affordable. By choosing this market-proven hardware, you can ensure the long-term stable use of doors and windows.

In general, when choosing thermally broken aluminum doors and windows, we must consider multiple factors comprehensively, and each detail is directly related to the use effect and life of the doors and windows. Choosing cost-effective thermally broken aluminum doors and windows is both beautiful and practical, bringing higher comfort and energy-saving effects to home life.

In general, when choosing thermally broken aluminum doors and windows, we must consider multiple factors comprehensively, and each detail is directly related to the use effect and life of the doors and windows. Choosing cost-effective thermally broken aluminum doors and windows is both beautiful and practical, bringing higher comfort and energy-saving effects to home life.

Profile thickness

In fact, the performance of aluminum profiles is not the thicker the wall thickness, the better. The material and cavity structure also play a key role.

Aluminum profiles are mainly divided into primary aluminum and recycled aluminum. Primary aluminum is refined and processed from aluminum ore and has high quality; recycled aluminum is made by remelting recycled waste aluminum products. Its performance is relatively inferior, but as a civilian aluminum material encouraged by the state, it has environmental value. A simple way to distinguish primary aluminum from recycled aluminum is to observe the cut surface: the cut surface of primary aluminum is flat, burr-free, and has a bright blue-black color; the cut surface of recycled aluminum is prone to burrs, and the color is silvery white.

In addition, the quality of aluminum profiles is also related to the aluminum alloy model. At present, 6063 aluminum alloys, such as 6063-T5 and 6063-T66, are widely used in door and window profiles. These types of aluminum alloys have excellent hardness and toughness and are the preferred materials for high-end profiles.

The performance of the profile is also closely related to the cavity structure. For example, profiles with multi-cavity structures perform better than single-cavity structures in terms of heat insulation and sound insulation. Under the same material and structural conditions, profiles with thicker walls perform better, but the cost will also increase. Therefore, to judge the quality of aluminum profiles, it is necessary not only to look at the wall thickness, but also to comprehensively consider the material and cavity structure to ensure that high-quality products are purchased.

Number of glass layers

Today's system windows are basically standard for hollow glass, mainly with double-layer hollow and triple-layer hollow options. High-end configurations usually use tempered glass with 5mm per layer. Triple-layer hollow glass is widely used in cold areas in winter, and its heat insulation and sound insulation performance are better than double-layer hollow glass.

Is there a choice with more layers? There are indeed four-layer hollow and even laminated glass, but in actual applications, double and triple layers are still the mainstream. Although the increase in the number of glass layers has improved some performance, it also brings the following problems:

Increased weight: Multi-layer glass increases the overall weight of the window, exerting greater pressure on the frame, which may cause deformation. Especially in the outward-opening windows commonly used in the south, excessive glass will accelerate the loss of hardware and even cause safety hazards.

Decrease in light transmittance: As the number of glass layers increases, the overall light transmittance will decrease, affecting the indoor lighting effect.

Visual distortion: After tempering, the glass will produce a certain degree of deformation. The more layers, the more obvious the distortion effect.

Rising costs: The increase in the number of glass layers also directly pushes up the production and installation costs.

Therefore, usually double or triple layers of hollow glass are sufficient to meet the thermal and sound insulation needs of most families. Unless there are special needs, such as extreme sound insulation, heat insulation or explosion-proof requirements, there is no need to choose too many layers of glass to avoid an imbalance between performance improvement and other problems.

Glass

Many door and window salespeople will recommend Low-E glass, which is indeed an excellent energy-saving technology. It can significantly improve the heat insulation performance of glass, effectively block ultraviolet rays, and have a certain privacy protection effect. However, Low-E glass is not suitable for all occasions.

First, it may not be suitable for families who like to grow flowers. Because Low-E glass reduces the transmission of ultraviolet rays, some plants may not get enough light to complete normal photosynthesis. Secondly, the light transmittance of Low-E glass is about 10% lower than that of ordinary glass. If it is a small apartment, especially in a space with poor lighting conditions, the use of this glass may further reduce the brightness of the room.

Therefore, when purchasing Low-E glass, you should combine the family's actual needs and the environment in which it will be used to ensure that you can enjoy the energy-saving effect without affecting your living comfort.

The number of sealing layers refers to the number of sealing structure layers between the door and window frames and sashes. Standard system doors and windows usually adopt a three- to five-layer sealing design. However, in order to attract consumers, some manufacturers will make the sealing strips into multiple convex ridges and promote them as eight-layer, ten-layer or even more-layer sealing structures. In fact, this statement is more of a marketing gimmick. Too many sealing layers may cause the strips to connect. Once one layer fails, other layers may fail together, thereby reducing the overall sealing performance.

The key to judging the sealing performance of doors and windows lies not only in the number of sealing layers but also in the material of the sealing strip. High-quality sealing strips usually use EPDM, which is an automotive-grade sealing material. Currently, high-end products also have EPDM soft and hard co-extruded strips, which have good elasticity, are not easy to age, have a bright and clean surface, and have no odor. And those sealing strips that look greasy and emit pungent odors are often of poor quality. Even if there are more sealing layers, it is difficult to guarantee the sealing performance of doors and windows with inferior strips.

Therefore, when purchasing doors and windows, you should pay attention to the material and design of the sealing strip rather than blindly pursuing the concept of "multi-layer sealing" to ensure the long-term performance and use experience of doors and windows.

Profile insulation strip

The broken bridge aluminum is named because a kind of insulation strip is embedded in the middle of the profile, forming a "thermal break" structure, which effectively prevents the transfer of heat.

So, is the wider the insulation strip, the better? Not really. If the insulation strip is too wide, the aluminum part will become smaller, which may reduce the overall strength of the profile and affect its stability and service life.

In addition, the material of the insulation strip is also crucial. Common insulation strip materials are divided into nylon PA66 and PVC. Nylon PA66 insulation strips are superior to PVC materials in terms of strength, heat resistance, and aging resistance. Therefore, when purchasing broken bridge aluminum doors and windows, you should pay attention not only to the width of the insulation strip but also to its material to ensure the reliability and superiority of the overall performance.

Hardware

Hardware is the "soul" of doors and windows, directly affecting their opening method, sealing, and service life. At present, common door and window hardware include traditional types such as inner opening, outer opening, and inner opening and tilting. In recent years, some high-end hardware has also appeared, such as hidden inner opening and tilting hardware and intelligent opening hardware.

When choosing door and window hardware, it is recommended to give priority to some traditional and common hardware types. These hardware technologies are mature, durable, not easy to damage, and more convenient to maintain and replace later, and the price is relatively affordable. By choosing this market-proven hardware, you can ensure the long-term stable use of doors and windows.