How to Ensure a Good Anodized Aluminum Trim Strip

Updated: 3 Aug 2022

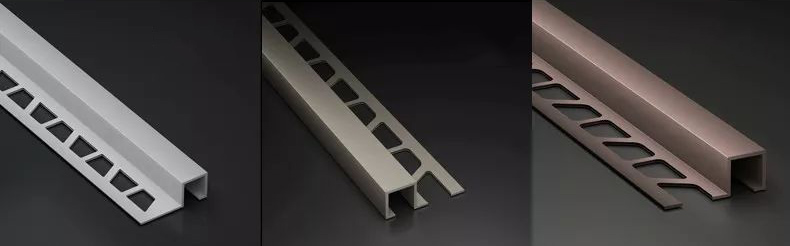

Outstanding anodized aluminum trim strip from Shenghai Aluminum

Many factories have difficulty producing a good finish in the anodized aluminum industry in a single pass. Of course, experienced aluminum profile manufacturers are highly skilled in oxidation technology. Like our company, we have over 13 years of experience in aluminum extrusion and deep processing. Customers have praised the anodized aluminum profiles in Europe, America, Australia, Mexico and Ecuador.

Aluminum is a very active metal chemically, and aluminum profiles can easily generate a thin (0.3-4 μm) and uneven oxide film in the atmosphere. This amorphous film has a poor gloss and lacks corrosion protection.

In industry, oxidation coloring is usually used to achieve a film layer of 10μm or more on the surface of aluminum profiles. The decorative effect and anti-corrosion properties are significantly improved. However, aluminum transition strip often appear dyed without color in the process of anodized coloring. What is the reason for this?

To anodized a good aluminum trim strip, you need to pay attention to these reasons

1. Anodized aluminum film not thick enoughThe solution is to check whether the anodic oxidation process is standard and whether the temperature, voltage, conductivity and other issues are stable. If there is an abnormality, we need to adjust the specification. If normal, you can properly go to extend the anodised time to ensure that the film thickness is up to standard.

2. Poor electrical conductivity

Poor electrical conductivity in bulk caused by poor contact between the copper anode rod or the cathode lead plate. We usually need to pay attention to cleaning the anode copper rod and cathode lead plate to ensure good contact.

3. Dye has decomposed or become moldy

In this case, you need to replace the dye or use an ht403 dye anti-mildew agent to prevent it.

4. PH value of the dye solution is too high

The PH value can be adjusted to the standard value with glacial acetic acid.

5. Anodized temperature is too low, resulting in a dense skin film

The anodised temperature can be raised appropriately.

6. The workpiece is left in the water bath for too long after anodized

Advocate timely dyeing. If this situation has occurred, the workpiece can be placed in the anodic oxidation tank or nitric acid neutralization tank with appropriate activation treatment before dyeing. The effect will be very good.

7. Improper choice of dyes. Need to use suitable dyes.

Aluminum trim strip is currently the most popular for anodized coloring. The colors are rich and affordable. Of course, we also have electrophoresis and powder coating so that you can choose any aluminum trim coloring solution.