How To Purchase Architectural Aluminum Profiles

Updated: 27 Apr 2025

Many people don't know how to choose aluminum profiles, and they are prone to choosing unqualified aluminum profiles. Therefore, Shenghai Aluminum has selected some of the following main viewpoints for you, which can inspire you and help you achieve better results in your architectural aluminum profile projects.

Aluminum architectural profile products refer to aluminum extrusion profiles that are used for doors, windows, guardrails, curtain walls and other buildings, without or with surface treatment. Due to its high strength, light weight, corrosion resistance, good decorativeness, long service life, rich colors and other advantages, it has become an important material for home decoration.

1. Anodized profiles refer to architectural aluminum profiles obtained by anodizing, anodizing plus electrolytic coloring, or anodizing plus organic coloring. The outstanding features of anodized profiles are strong metallic texture and good corrosion resistance.

Product performance and application: Anodized profiles are widely used as building components or vehicle components, such as door and window materials, curtain wall materials, guardrails, etc.

Product main technical indicators: in accordance with the “Aluminum Alloy Building Profiles Part 2: Anodized Profiles” GB/T 5237.2-2017 standard.

2. Electrophoretic profiles refer to aluminum alloy profiles that are pre-treated, and charged paint particles are moved to the surface of the aluminum profile by electricity and then cured in water to form a complete coating.

Product performance and application: Compared with the traditional spraying process, electrophoretic paint coating has high quality, good corrosion resistance, environmental protection and energy saving, and wide application.

Main technical indicators of the product: in line with the standard of “Aluminum Alloy Building Profiles Part 3: Electrophoretic Paint Profiles” GB/T 5237.3-2017.

3. Powder coating profiles are electrostatic powder spraying profiles for buildings with thermosetting polyester, polyurethane, trifluoroethylene-vinyl ether (PEVE) powder and thermoplastic polyvinylidene fluoride (PVDF) powder as coatings.

Product performance and application: a variety of colors, good corrosion resistance, good weather resistance, good wear resistance, good coating adhesion, easy to clean and scrub, and the minimum local thickness of the coating on the decorative surface is ≥40μm. Widely used in architectural decoration, eg: LED profile, aluminum trim profile, aluminum ceiling, etc.

Main technical indicators of the product: in line with GB/T 5237.4-2017 ”Aluminum Alloy Building Profile Part 4: Powder Spraying Profile”.

4. Fluorocarbon spraying profile refers to the electrostatic spraying aluminum alloy hot extrusion profile for construction with organic solvent-based or water-based solvent-based polyvinylidene fluoride (PVDF) paint as the film layer.

Product performance and application: anti-fading, anti-frosting, anti-air pollution (acid rain, etc.) corrosion resistance, its anti-ultraviolet ability and crack resistance are strong, and it can also withstand the influence of bad weather and environment. Its excellent performance is beyond the reach of general coatings.

Main technical indicators of the product: in line with GB/T 5237.5-2017 “Aluminum Alloy Building Profile Part 5: Spraying Paint Profile” standard.

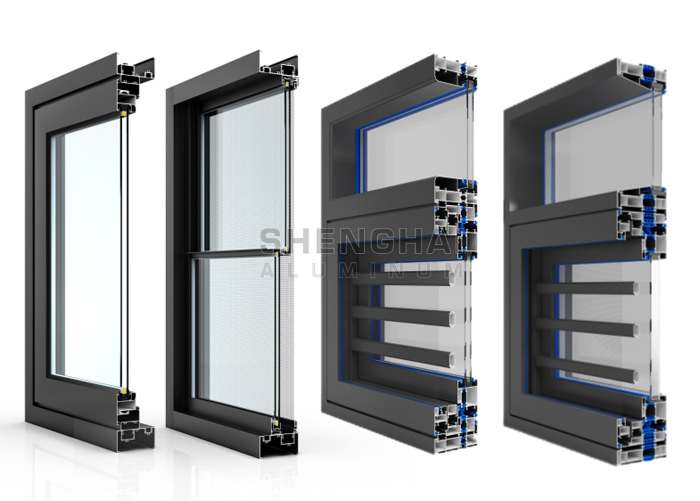

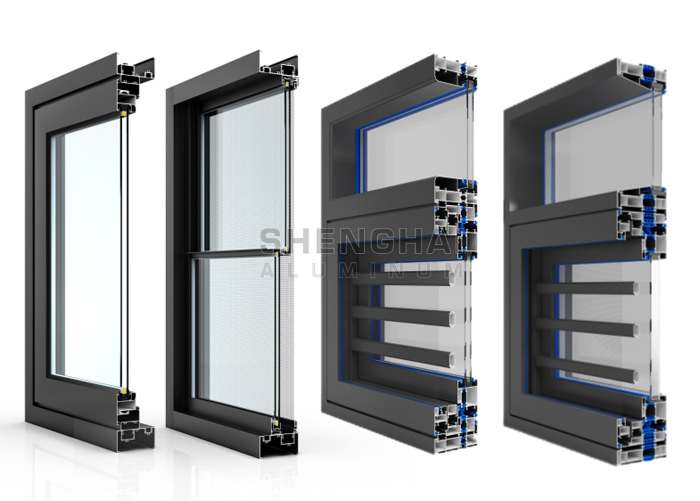

5. Aluminum alloy building insulation profile refers to a composite profile with insulation function made by connecting aluminum alloy profiles with insulation materials. Simply put, an “insulating belt” is added between two aluminum alloy profiles to interrupt the heat transfer function of the metal.

Product performance and application: energy saving, sound insulation, anti-condensation, high strength, good air tightness and water tightness. Main technical indicators of the product: in line with GB/T 5237.6-2017 ”Aluminum Alloy Building Profiles Part 6: Insulating Profiles”.

Some customers will experience deformation when using aluminum doors and windows. In fact, this is because the thickness of the profiles purchased by consumers for aluminum alloy doors and windows is different, which leads to deformation of aluminum doors and windows. Generally speaking, the thickness of aluminum alloy doors and windows that meet national standards is more than 1.2mm, but some small manufacturers use aluminum alloy profiles with a thickness of less than 1.2mm in order to reduce production costs. This type of profile is easy to deform because the thickness of the material does not meet the standard. The thickness of the profile directly determines the quality of aluminum alloy doors and windows. Therefore, when we choose the manufacturer of aluminum profiles for doors and windows, we can strictly require the manufacturer to extrude the thickness of the aluminum profile according to our requirements to ensure the quality of aluminum doors and windows.

2. Check the coating thickness

When purchasing, you can lightly scratch the surface of the profile to see if the oxide film on the surface can be wiped off.

3. Check the color, flatness, and glossiness

The color of the same aluminum alloy profile should be consistent. If the color difference is obvious, it is not suitable for selection. Check the surface of the aluminum alloy profile; there should be no dents or bulges. Aluminum alloy door and window profiles should avoid profiles with open bubbles (white spots) and ash (black spots) on the surface, as well as obvious defects such as cracks, burrs, and peeling.

4. Check the hardware accessories

Aluminum alloy doors and windows are mostly installed in humid environments such as bathrooms and kitchens, so pulleys, hardware hinges, door locks, door and window handles, etc. The quality of accessories directly affects the service life of aluminum alloy doors and windows. Reminder: The quality of accessories used in aluminum alloy doors and windows sold on the market varies greatly. Products of regular brands generally use galvanized accessories with high corrosion resistance and not easy to rust, while some small manufacturers will match ordinary iron accessories. Therefore, when choosing aluminum door and window hardware accessories, you can directly cooperate with aluminum manufacturers to provide one-stop service, which is conducive to quality control and cost saving.

5. Check the sealing performance

Most aluminum alloy doors in the building materials market are inlaid with artistic glass of various colors. These glasses are single-layer and double-layer hollow glass with strong three-dimensional sense and good sound insulation effect.

Shenghai Aluminum recommends that you pay attention to the sealing performance when choosing aluminum alloy doors with inlaid glass, especially products with hollow glass designs. If the sealing is not good, the hollow layer will be dirty and dirty, affecting the appearance. Brand products use high-quality sealing strips and advanced hot-pressing sealing technology for all-around sealing treatment, which can effectively prevent dust and water and have outstanding sound insulation effect.

Reminder: To check the sealing of the glass interlayer of the aluminum alloy door, in addition to checking whether the glass glue coating on the front is tight, you should also check whether the sealing strip on the back glass of the door is flat, and there should be no curling or de-grooving.

6. Observe the processing quality

High-quality aluminum alloy profiles are finely processed and beautifully welded without scratches, bubbles, stains, etc. It can provide high-quality aluminum profile products for the construction industry.

7. Profile section

Many extrusion factories choose recycled aluminum bars to save costs, but this will affect the quality of aluminum alloy products. So when we get samples from aluminum profile manufacturers, we should pay attention to whether the color of the profile section is gray or black, whether there are pores, and whether there is stratification. You can also measure the hardness and density to confirm whether it meets the aluminum alloy profile supplier required by the company.

When choosing architectural profile aluminum, you need to consider many aspects. You should consider both the quality and whether the supplier is trustworthy. It is very important to choose a reliable aluminum profile supplier to ensure the quality of your products and the delivery date. Shenghai Aluminum is an aluminum profile extrusion factory with 15 years of production experience. It can provide you with one-stop services for extrusion and deep processing. Choose us to provide you with professional aluminum building profile solutions, get free samples and quotations, and look forward to your reply.

When choosing architectural profile aluminum, you need to consider many aspects. You should consider both the quality and whether the supplier is trustworthy. It is very important to choose a reliable aluminum profile supplier to ensure the quality of your products and the delivery date. Shenghai Aluminum is an aluminum profile extrusion factory with 15 years of production experience. It can provide you with one-stop services for extrusion and deep processing. Choose us to provide you with professional aluminum building profile solutions, get free samples and quotations, and look forward to your reply.

Aluminum architectural profile products refer to aluminum extrusion profiles that are used for doors, windows, guardrails, curtain walls and other buildings, without or with surface treatment. Due to its high strength, light weight, corrosion resistance, good decorativeness, long service life, rich colors and other advantages, it has become an important material for home decoration.

Types and uses of architectural aluminum profiles

At present, the types of architectural aluminum profiles sold on the market are mainly divided into anodized profiles, electrophoretic profiles, powder coated profiles, fluorocarbon sprayed profiles, and thermal insulation profiles.1. Anodized profiles refer to architectural aluminum profiles obtained by anodizing, anodizing plus electrolytic coloring, or anodizing plus organic coloring. The outstanding features of anodized profiles are strong metallic texture and good corrosion resistance.

Product performance and application: Anodized profiles are widely used as building components or vehicle components, such as door and window materials, curtain wall materials, guardrails, etc.

Product main technical indicators: in accordance with the “Aluminum Alloy Building Profiles Part 2: Anodized Profiles” GB/T 5237.2-2017 standard.

2. Electrophoretic profiles refer to aluminum alloy profiles that are pre-treated, and charged paint particles are moved to the surface of the aluminum profile by electricity and then cured in water to form a complete coating.

Product performance and application: Compared with the traditional spraying process, electrophoretic paint coating has high quality, good corrosion resistance, environmental protection and energy saving, and wide application.

Main technical indicators of the product: in line with the standard of “Aluminum Alloy Building Profiles Part 3: Electrophoretic Paint Profiles” GB/T 5237.3-2017.

3. Powder coating profiles are electrostatic powder spraying profiles for buildings with thermosetting polyester, polyurethane, trifluoroethylene-vinyl ether (PEVE) powder and thermoplastic polyvinylidene fluoride (PVDF) powder as coatings.

Product performance and application: a variety of colors, good corrosion resistance, good weather resistance, good wear resistance, good coating adhesion, easy to clean and scrub, and the minimum local thickness of the coating on the decorative surface is ≥40μm. Widely used in architectural decoration, eg: LED profile, aluminum trim profile, aluminum ceiling, etc.

Main technical indicators of the product: in line with GB/T 5237.4-2017 ”Aluminum Alloy Building Profile Part 4: Powder Spraying Profile”.

4. Fluorocarbon spraying profile refers to the electrostatic spraying aluminum alloy hot extrusion profile for construction with organic solvent-based or water-based solvent-based polyvinylidene fluoride (PVDF) paint as the film layer.

Product performance and application: anti-fading, anti-frosting, anti-air pollution (acid rain, etc.) corrosion resistance, its anti-ultraviolet ability and crack resistance are strong, and it can also withstand the influence of bad weather and environment. Its excellent performance is beyond the reach of general coatings.

Main technical indicators of the product: in line with GB/T 5237.5-2017 “Aluminum Alloy Building Profile Part 5: Spraying Paint Profile” standard.

5. Aluminum alloy building insulation profile refers to a composite profile with insulation function made by connecting aluminum alloy profiles with insulation materials. Simply put, an “insulating belt” is added between two aluminum alloy profiles to interrupt the heat transfer function of the metal.

Product performance and application: energy saving, sound insulation, anti-condensation, high strength, good air tightness and water tightness. Main technical indicators of the product: in line with GB/T 5237.6-2017 ”Aluminum Alloy Building Profiles Part 6: Insulating Profiles”.

Tips for purchasing Architectural aluminum profiles

1. Check the thicknessSome customers will experience deformation when using aluminum doors and windows. In fact, this is because the thickness of the profiles purchased by consumers for aluminum alloy doors and windows is different, which leads to deformation of aluminum doors and windows. Generally speaking, the thickness of aluminum alloy doors and windows that meet national standards is more than 1.2mm, but some small manufacturers use aluminum alloy profiles with a thickness of less than 1.2mm in order to reduce production costs. This type of profile is easy to deform because the thickness of the material does not meet the standard. The thickness of the profile directly determines the quality of aluminum alloy doors and windows. Therefore, when we choose the manufacturer of aluminum profiles for doors and windows, we can strictly require the manufacturer to extrude the thickness of the aluminum profile according to our requirements to ensure the quality of aluminum doors and windows.

2. Check the coating thickness

When purchasing, you can lightly scratch the surface of the profile to see if the oxide film on the surface can be wiped off.

3. Check the color, flatness, and glossiness

The color of the same aluminum alloy profile should be consistent. If the color difference is obvious, it is not suitable for selection. Check the surface of the aluminum alloy profile; there should be no dents or bulges. Aluminum alloy door and window profiles should avoid profiles with open bubbles (white spots) and ash (black spots) on the surface, as well as obvious defects such as cracks, burrs, and peeling.

4. Check the hardware accessories

Aluminum alloy doors and windows are mostly installed in humid environments such as bathrooms and kitchens, so pulleys, hardware hinges, door locks, door and window handles, etc. The quality of accessories directly affects the service life of aluminum alloy doors and windows. Reminder: The quality of accessories used in aluminum alloy doors and windows sold on the market varies greatly. Products of regular brands generally use galvanized accessories with high corrosion resistance and not easy to rust, while some small manufacturers will match ordinary iron accessories. Therefore, when choosing aluminum door and window hardware accessories, you can directly cooperate with aluminum manufacturers to provide one-stop service, which is conducive to quality control and cost saving.

5. Check the sealing performance

Most aluminum alloy doors in the building materials market are inlaid with artistic glass of various colors. These glasses are single-layer and double-layer hollow glass with strong three-dimensional sense and good sound insulation effect.

Shenghai Aluminum recommends that you pay attention to the sealing performance when choosing aluminum alloy doors with inlaid glass, especially products with hollow glass designs. If the sealing is not good, the hollow layer will be dirty and dirty, affecting the appearance. Brand products use high-quality sealing strips and advanced hot-pressing sealing technology for all-around sealing treatment, which can effectively prevent dust and water and have outstanding sound insulation effect.

Reminder: To check the sealing of the glass interlayer of the aluminum alloy door, in addition to checking whether the glass glue coating on the front is tight, you should also check whether the sealing strip on the back glass of the door is flat, and there should be no curling or de-grooving.

6. Observe the processing quality

High-quality aluminum alloy profiles are finely processed and beautifully welded without scratches, bubbles, stains, etc. It can provide high-quality aluminum profile products for the construction industry.

7. Profile section

Many extrusion factories choose recycled aluminum bars to save costs, but this will affect the quality of aluminum alloy products. So when we get samples from aluminum profile manufacturers, we should pay attention to whether the color of the profile section is gray or black, whether there are pores, and whether there is stratification. You can also measure the hardness and density to confirm whether it meets the aluminum alloy profile supplier required by the company.