What is Hard Anodized Finish for Aluminum Profiles

Updated: 22 Jun 2022

About Hard Anodized Finish Aluminum

Anodizing is an electrolytic passivation process. In this process, a thin layer of anodized aluminum is formed on the profile's outer surface, improving durability and appearance. This anodized aluminum is not applied to the surface like paint or electroplating but is fully integrated into the aluminum metal structure and, therefore, will not chip or flake. However, suppose the acid solution is cooled to the freezing point of water, and the flow of electricity is increased significantly. In that case, the process is called hard anodizing.Hard anodised is known as hard aluminum oxide treatment. Hard anodized finish is characterized by thick oxide film and high hardness and is often used for wear resistance, heat resistance, and insulation. The main purpose is to improve the various properties of aluminum and aluminum alloy profiles, including corrosion resistance, wear resistance, weather resistance, insulation, and adsorption. It is suitable for aluminum extrusion profiles and may be used for die-casting aluminum alloy parts.

Hard Anodized VS Anodized - Aluminum Profiles

We usually say about aluminum profile oxidation, mainly about standard anodic oxidation. But sometimes we hear the term hard anodizing. Hard anodized is not the anodizing with a little thicker oxide film. They are different processes. There are three main differences in the process of hard anodised and standard anodizing of aluminum profiles.1. Electrolyte concentration difference: Normal anodized concentration is around 20%; hard oxidation is generally at 15% or lower.

2. Current/voltage difference: ordinary anodized current density is generally 1-1.5A/dm2; hard anodizing current is higher, 1.5-3A/dm2.

3. Temperature difference: ordinary anodised water temperature is around 18-22 ℃, with additives can reach 30 ℃, the temperature is too high easy to appear powder or crack; hard anodized is generally below 5 ℃, relatively speaking, the lower the temperature, the higher the hard.

Advantage of Anodized Aluminum

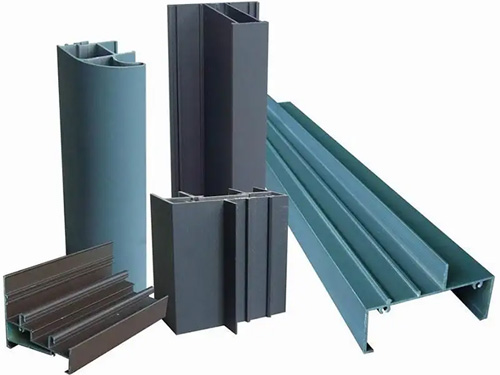

Anodizing provides an attractive, low-maintenance, highly durable and long-lasting material for exterior, curtain wall, edge trim, heat sink, windows and doors.1. Durability

The anodizing treatment can thicken the film layer, which can resist the corrosion of various acid and alkali substances and improve the service life of aluminum profiles.

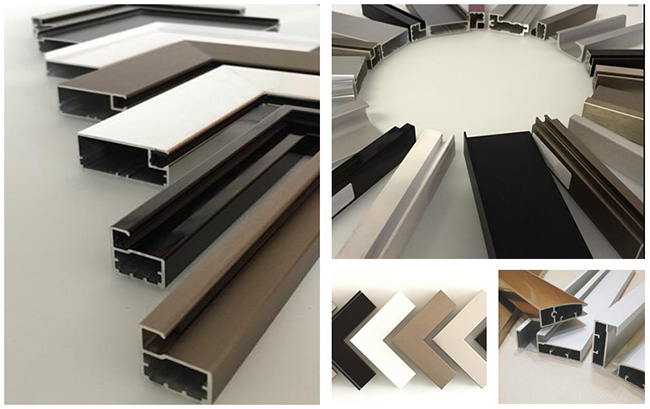

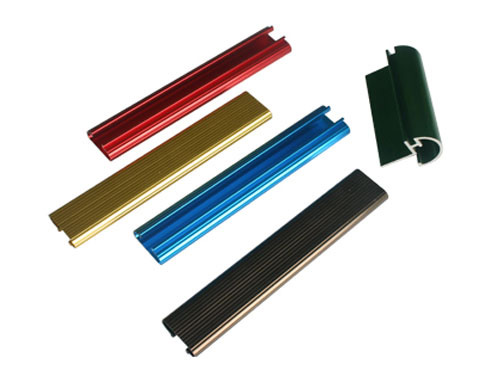

2. Improve the decorative performance

The surface of aluminum profiles produced by extrusion presents the original color of aluminum, silver-white, and through anodic oxidation treatment, it can be turned into various colors such as golden yellow, brown, red and other shades based on the original silver-white color by oxidation coloring technology according to the requirements of customers and usage needs, which improves the decorative performance of aluminum profiles.

3. Easy maintenance

Anodized aluminum products, stable performance. Cleaning anodized aluminum products directly with water.

4. Health and safety

After anodizing to generate a protective film on the surface, forming a new insulating material that does not have electrical conductivity and can protect the safety of electronic components, suitable for use in the production of electronic products.

5. Various mechanical pre-treatments for different metal finishes: sandblasting, polishing and three types of brushed patterns.

Shenghai Aluminum can provide anodized aluminum, hard anodizing aluminum, clear satin anodized aluminum, silver anodized finish, bright anodized aluminum, etc.

Suppose you need anodized aluminum finishes for windows, doors, aluminum edge trim, aluminum handles, electronics, or curtain walls. In that case, you can rely on China Shenghai Aluminum Manufacturer to provide the quality. We offer a variety of standard finishes as well as many other custom polished anodized aluminum finishes to help create the exquisite appearance you need. Please contact our customer service team for more information on our aluminum anodizing services.