Why Are There Scratches on Surface of Aluminium Extrusion Profile

Updated: 7 Jun 2021

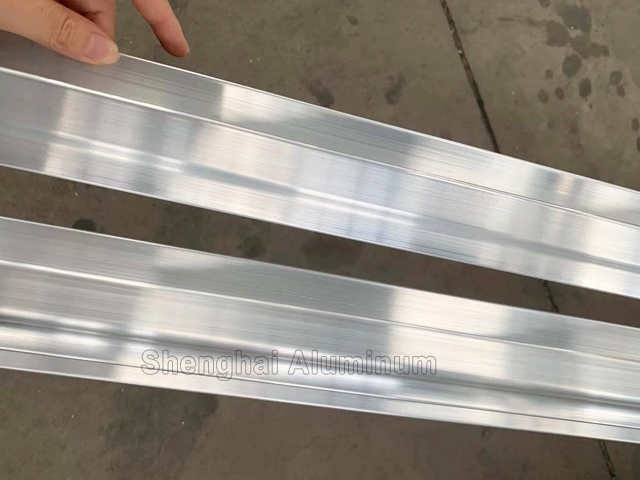

Many there are scratches on the surface of the industrial aluminium extrusion profile. How to prevent extruded aluminium frame scratches? SHENGHAI summarized six reasons.

1. There is dirt on aluminum ingot surface

For example, there are dirt and ingot shrinkage on the surface of the aluminum ingot, or there are hard metal particles in the ingot. When the metal material flows through the working belt during the extrusion process, this shrinkage and floatation or hard metal material particles adhere to the surface of the working belt or cause damage to the working belt. The dirt will damage the surface of industrial profiles;

2. Placement rate

When the fork rod sends extruded aluminium channel from the discharge rail to the swing bed. Excessive speed will cause scratches on the extrusion profile;

3. Die extrusion

If the mold is stained with something dirty, the aluminum profile will be scratched during the extrusion process. So there will be scratches;

4. Human drag

Dragging industrial aluminum profiles by the human on the side of the swing bed will cause scratches on the surface;

5. Dirty countertop

There is bare metal on the discharge track or swing bed or hard inclusions in the graphite strips. When it comes into contact with industrial aluminum profile, it will scratch the surface of the aluminum profile;

6. Whole process of transportation

During transportation, industrial extruded aluminium profiles rub or squeeze each other to cause damage;

SHENGHAI summarizes six reasons. About why there are scratches on the surface of industrial aluminum profiles. I believe that aluminum profile manufacturers will pay more attention to these details during the production process, thereby improving production efficiency.

If you want to know more about industrial aluminum extrusion profile, please feel free to contact us.

https://shenghai-alu.com

sales@shenghai-alu.com