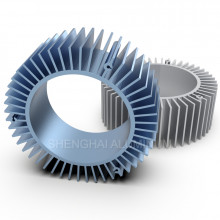

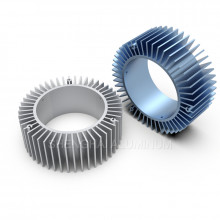

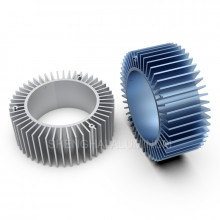

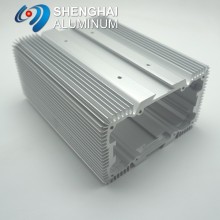

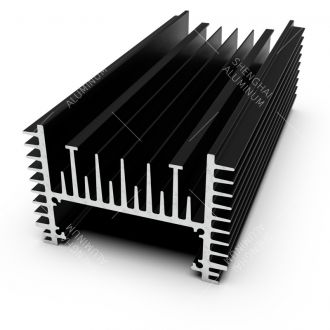

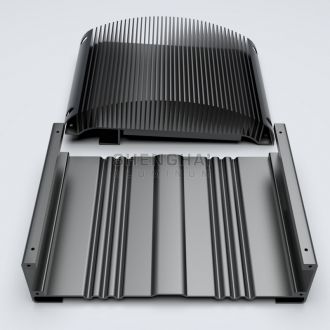

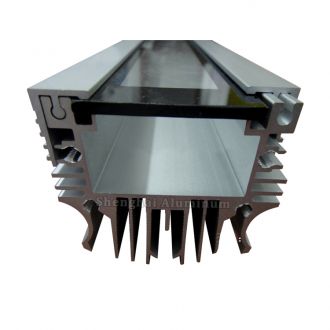

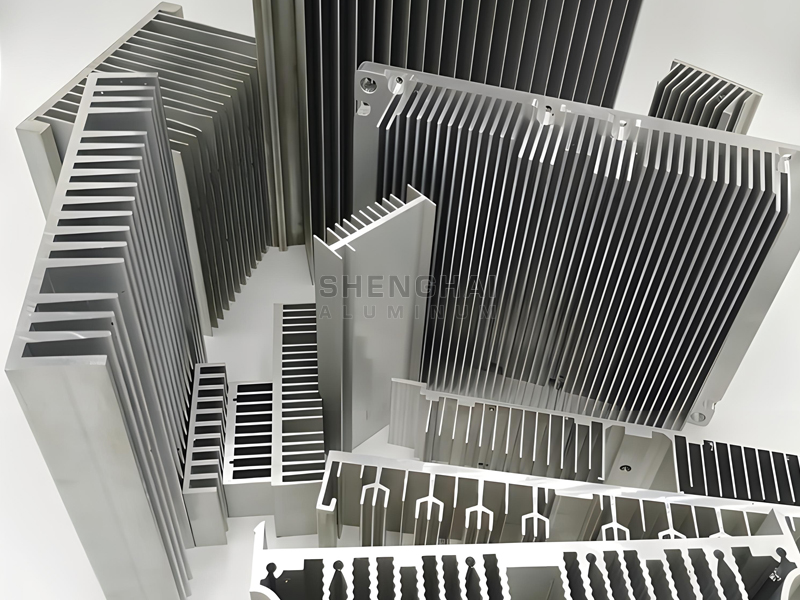

CNC Anodized Aluminum Extrusion Heat Sink Profiles

Grade:

6061/6063 Series

Temper:

T5-T6

Color:

Mill Finished

Material & Temper:

Aluminum 6063-T5 / 6061-T6

Thickness:

0.5mm-12mm Customized for aluminum

Precision:

+-0.15mm

Surface Treatment:

Mill finish, powder coated, anodized, electrophoresis, Polishing

Machining:

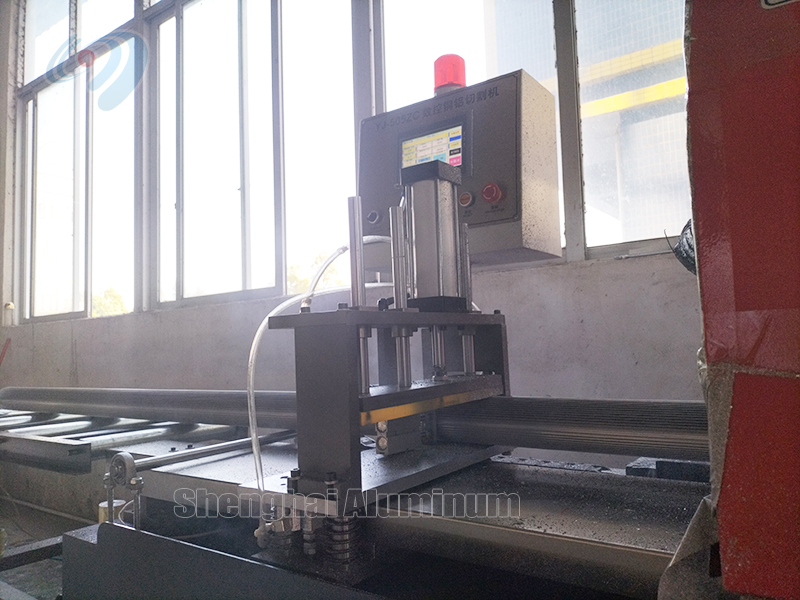

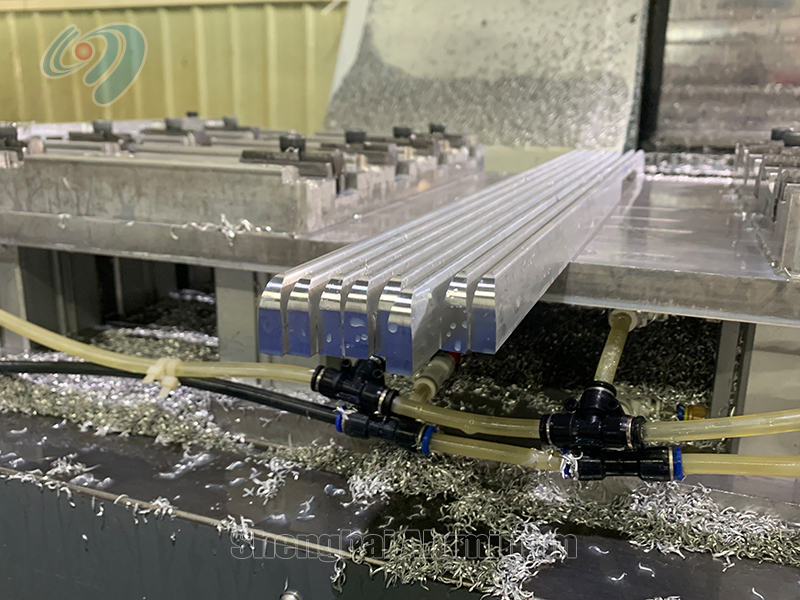

High Precision CNC Machining

Deep Process:

Precise cutting, drilling, milling, fabricating

Feature:

High quality, anti-scratch, anti-deformation

Length:

Custom Available

Product Description

Extruded heat sink, also known as heat sink extrusion or aluminum extrusion heat sink, has the advantages of beautiful appearance, lightweight, good heat dissipation performance and good energy-saving effect.As a manufacturer of aluminum extrusion heatsinks, we can supply any type of heat sink. Such as electronic heatsink, heat sink cooling fans, aluminum heat sink plate, LED heat sink, etc.

Aluminium 6063 is a commonly used aluminum heatsink material with good thermal conductivity and processability. With its long-accumulated technical experience and production process, SHENGHAI creates aluminum alloy profiles with good thermal conductivity and other characteristics and develops customized heatsink profiles to meet customers' product differentiation, specialization, and personalization requirements. The surface of the finished extruded heat sink is anodized to improve the aluminium's corrosion resistance, wear resistance, and appearance. The commonly used aluminum heatsinks extrusion in China are electronic heat sinks, computer heat sinks, sunflower heat sinks, power semiconductor heat sinks, etc.

We have professional aluminum profile deep processing equiment. Such as CNC machines, powder coated, anodized, electrophoresis, polishing, punching,ect. Shenghai Aluminium Extrusion Profiles is one of the leading manufacturers.Can provide professional production extruded aluminum heat sink solutions.We provide you with Quality, Time and Price.

Service We provide:

1. Professional technical team Suggestions improvement for you about your product drawings.

2. Professional quality inspectors to Ensure the quality and compliance of your products.

3. Professional staff to match custom colors for you,make samples for you if you need.

4. Professional die development capabilities.

5. Professional aluminum manufacturer experience, more than 10 years.

Product Feature:

1.High quality aluminum alloy profiles, thickness 0.4mm-20mm or customized.

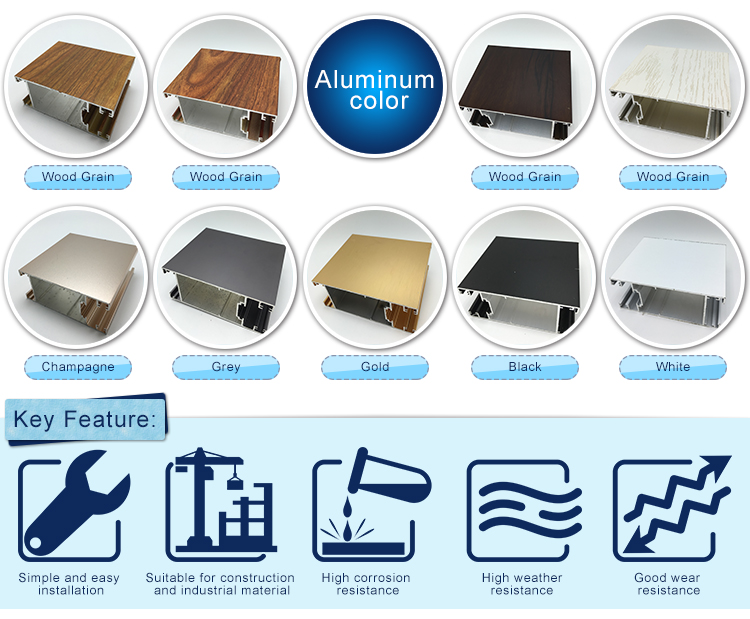

2.Color: Silver, Champagne, Bronze, Golden, Black, Wood grain, Sand coating, Anodized Acid and alkali or Customized.

Product Application

LED Lighting

Central processing units (Computers, TV)

Motor

Transistors, Lasers

Forced Air Heating and Cooling

Solar Thermal Systems

Other electronic equipment

Our Factory

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Leave a Message