Heat Sink

Heat sinks are mainly formed by extrusion of aluminum 6063 or 6061. Their shapes are generally designed to be sunflower-shaped, flat and wide, round, comb-shaped, fishbone-shaped, or fin-shaped, among others, to improve the heat dissipation effect. Heat sink aluminum is the best choice for various components. It not only has a a good heat dissipation effect but also has a lightweight and a suitable price. It is widely used in electronic equipment, the new energy industry, the automotive industry and other fields.

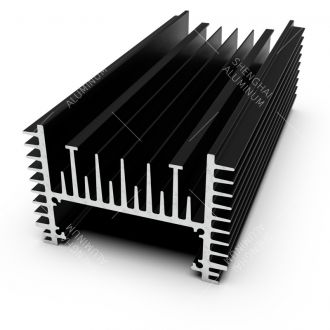

heatsink

Black Anodized Aluminum Electronic Heat Sink Plate for Poland

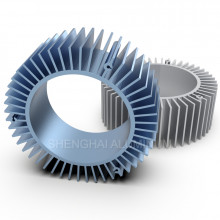

Heat Sink

Anodized Silver Aluminum Extrusion Heatsink Surface Profile

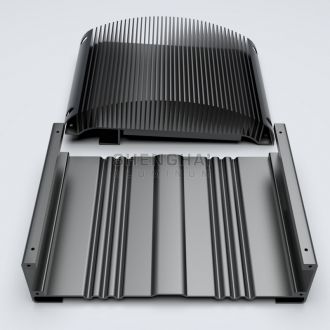

heat sink

CNC Anodized Aluminum Extrusion Heat Sink Profiles

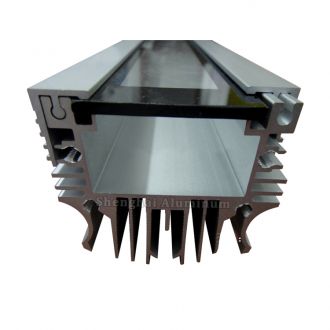

Heatsink

Black Anodised Aluminum Heatsink for Electrical Enclosure

Heat Sink Plate

Aluminium Heat Sink Plate For Electronic Components

SH-LED-004

SH-LED-004 Aluminium Profile for LED Strip Lighting

SH-LED-005

SH-LED-005 Aluminium Heatsink Extrusion Profile

7R./P1

1

Leave a Message

What Is Heat Sink Aluminum

Heat sinks are mainly formed by extrusion of aluminum 6063 or 6061. Their shapes are generally designed to be sunflower-shaped, flat and wide, round, comb-shaped, fishbone-shaped, or fin-shaped, among others, to improve the heat dissipation effect. Heat sink aluminum is the best choice for various components. It not only has a a good heat dissipation effect but also has a lightweight and a suitable price. It is widely used in electronic equipment, the new energy industry, the automotive industry and other fields.Some people may wonder why aluminum alloy is used to make heat sinks. In fact, aluminum profiles exhibit high thermal conductivity, efficient heat dissipation, rapid heat dissipation, and high metal thermal strength. In addition, heat sink aluminum is anodized to produce a layer of oxide film, which can better protect the heat sink. Enhance the corrosion resistance of aluminum heat sinks to increase their service life. It also has better bearing capacity and is a good component for various products that need heat dissipation.

Advantages of Heat Sink Aluminum

Heat sink aluminum is becoming increasingly widely used and popular among users, primarily due to the unique advantages of aluminum heat sinks.1. Corrosion resistance and long service life. A thick and solid oxide film can be formed on the surface of aluminum alloy materials, which can be used for a long time in heating water with a pH of ≤9 or in car water tanks, and heat sink aluminum with special surface treatment can be used for a long time in various materials with a pH of ≤12.

2. Various surface treatments can be performed, offering a wide variety of colors and patterns, with no welding points. This results in strong decorativeness, making the product beautiful, durable, and suitable for meeting everyone's personalized needs.

3. Safe to use and high pressure bearing. Because the specific strength and specific stiffness of aluminum alloy are much higher than those of copper, cast iron and steel. Even in the case of a thin thickness, it can withstand sufficient pressure, bending force, tension, and impact force and will not show damage during transfer, installation, and use.

4. Light weight, easy to install and transfer. In terms of heat dissipation, its weight is only one-eleventh of cast iron heat sink, one-sixth of steel heat sink, and one-third of copper heat sink, which can greatly save transportation costs, reduce labor intensity, and save installation time.

5. Simple installation and convenient maintenance. Because aluminum alloy has a low density and can be processed into various shapes and standard parts, the cross-section of this extrusion aluminum heat sink is large and regular, and the product assembly and surface treatment can be completed in one step. It can be directly installed on the construction site, saving a lot of installation costs. It is also convenient to repair and the price is low.

6. Energy saving and consumption reduction, low cost of use. When the distance between the heat sink inlet and outlet and the heat conduction temperature are the same, the heat sink aluminum heat sink has a heat dissipation capacity 2.5 times higher than that of the cast iron heat sink. Because of its beautiful appearance, it does not need a heating cover,

It can reduce heat loss by more than 30% and reduce costs by more than 10%. Although the heat dissipation effect of the aluminum heat sink is slightly inferior to that of the copper heat sink, its weight can be greatly reduced. Because the price of aluminum is only 1/3 of that of copper, it can reduce costs.